Watering Your Forklift Battery

Low electrolyte level in a cell can cause the plates to oxidize and shorten the life of the cell and the battery. To prevent this needless and wasteful damage, water should be added often enough to keep the electrolyte level above the perforated separator protectors. Ideally, a watering policy or schedule should be adopted and followed strictly. One of two systems can be used. In the first, the electrolyte level of two or three cells is checked each time the battery is charged. In the second, water is added to all of the batteries assigned to each charging area on a regular time schedule. The electrolyte levels are also spot-checked periodically to determine if the proper levels are being maintained.

Determining a reasonable and proper battery watering time schedule could be easy or difficult, depending on how widely the following three factors vary:

- Frequency of charge (daily, 1 1/2 times a day, three times a week, etc.)

- Water storage capacity of the specific cell type

- Age and condition of the battery. Older batteries and those in poor condition will consume water more rapidly than newer batteries and those in good condition. Also, some cell types have a greater water storage capacity than others.

Depending on the preceding variable factors, the batteries assigned to a specific charging area will require watering at different intervals. The frequency of watering is best determined by firsthand experience. EXAMPLE: If some batteries have low electrolyte levels when a weekly watering schedule is followed, change the schedule to twice a week. The electrolyte level should still be spot-checked periodically to determine if the proper levels are being maintained.

Adding Water

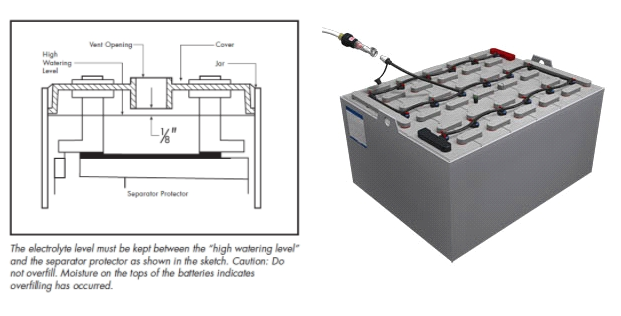

Generally, a certain amount of water loss is normal in all batteries, and it should be replaced with “pure” tap water or distilled water. In some areas around the country, tap water may contain chemicals or other impurities harmful to batteries. If in doubt about the suitability of the local tap water, always take the safe route and use distilled water.” If water is needed, add just enough to bring the electrolyte to the proper level as illustrated BELOW and also in the “Top 10 Ways to Care for Your Battery” article, which is available upon request and posted on www.forkliftexpress.com.

Batteries should be filled only at the end of the charging cycle. Overfilling is the most common error made when watering because it can cause tray corrosion and loss of capacity. Since corrosion can cause EXTENSIVE DAMAGE to batteries and vehicles, extreme caution must be taken to avoid overfilling the batteries.

The easier solution is a single point watering system, which fills each your battery’s cells to the perfect level with minimal labor. A single point watering system is simply a series of caps and hoses that stays on your forklift and can be connected to a single hose. Water will flow throughout the series of hoses and once each cell fills to the exactly specified level, the cap on that cell will close and keep over-watering from occurring. Call Forklift Express for a free quote on a single point watering system and save your company thousands on batteries and repairs.